New sodium-ion battery technology with high energy density and low cost is paving the way for $20,000 electric vehicles, while also enabling stable operation even at -40°C.

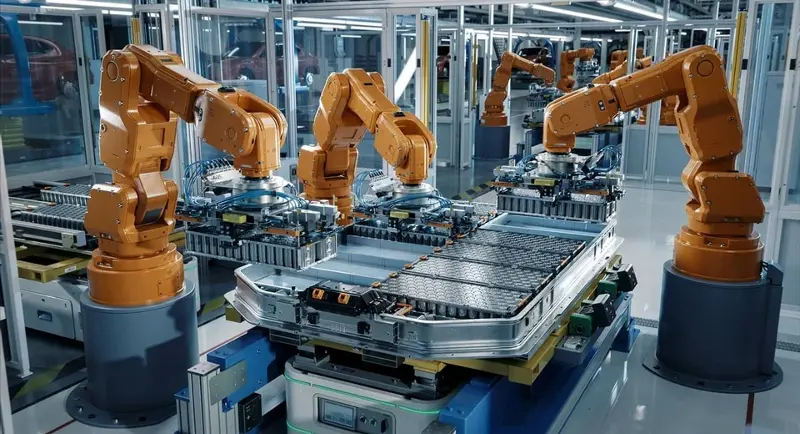

The electric vehicle (EV) industry is witnessing a historic transformation as sodium-ion batteries officially enter widespread commercialization. Once considered a secondary technology, sodium is now a formidable competitor to lithium batteries thanks to advances from major players like CATL and Zhaona New Energy. This shift not only addresses cost issues but also overcomes inherent limitations in harsh operating conditions.

Energy density surpasses technical barriers.

In April 2025, CATL launched its Naxtra brand of sodium-ion batteries and officially began mass production in December of the same year. Notably, the new battery cells achieved an energy density of 175 Wh/kg, surpassing the average 160–170 Wh/kg of currently popular lithium iron phosphate (LFP) batteries. This performance allows large electric vehicles to achieve a range of up to 500 km, putting sodium-ion batteries in a competitive position in the market.

In addition, Zhaona New Energy also made its mark with a solid-state sodium-ion battery prototype achieving an impressive energy density of 348.5 Wh/kg. By using a ceramic coating structure and eliminating the anode, this technology not only increases energy density but also improves long-term stability, approaching the performance of high-end NMC lithium batteries.

Superior advantages in terms of cost and safety.

Sodium-ion batteries possess three core advantages that are changing the cost structure of electric vehicles: low cost, durability in cold conditions, and safety during transport. Because sodium is readily available in sea salt and does not require expensive materials like cobalt or nickel, production costs are drastically reduced. Specifically, analysts predict that the price of sodium-ion batteries could fall to $40/kWh, significantly lower than the current $70/kWh price of LFP batteries.

| Criteria | Sodium-ion (Naxtra) battery | Standard LFP battery |

|---|---|---|

| Energy density | 175 Wh/kg | 160–170 Wh/kg |

| Estimated cost | 40 USD/kWh | 70 USD/kWh |

| Performance at -40°C | Maintain 90% capacity | Significant reduction |

In particular, its ability to operate in freezing conditions is a major advantage. Naxtra batteries can retain 90% of their capacity even at temperatures as low as -40°C, completely eliminating concerns about reduced operating range for users in cold climates. In terms of safety, this type of battery can discharge to 0.0V without damage or short circuits, making storage and transportation simpler and less risky than with lithium batteries.

The global race and hybrid battery solutions.

Currently, China is leading the race with the participation of CATL, BYD, and HiNa Battery. BYD has begun producing sodium-ion batteries for its low-cost electric vehicles at its Qinghai factory. Meanwhile, other countries such as India (Reliance), France (TIAMAT), and the US (Natron Energy) are also stepping up investment to reduce their dependence on imported lithium supplies.

Another notable trend is the hybrid battery design, combining sodium-ion and lithium-ion batteries. In this system, the sodium battery handles fast charging and operation in cold weather, while the lithium battery provides high energy density for long journeys. This approach allows manufacturers to optimize the balance between performance and cost depending on regional needs.

Overall, while lithium batteries still hold the advantage in the high-performance sports car segment, sodium-ion batteries are gradually becoming the most practical choice for the vast majority of consumers. With the potential to bring electric vehicles down to $20,000 without subsidies, sodium is key to driving the next phase of global electrification.